Icf blocks sizes plus#

The Reinforcer is compatible with Amvic’s Standard R22 ICF brick ledge forms in both 6” and 8”, the Amvic R30 Plus 6” and the fabricated brick ledge extension. The Amvic Brick Ledge Reinforcer eliminates the horizontal rebar and stirrups in the ledge area allowing the Reinforcer to be easily placed into the form in one step providing cost savings of up to 30% when factoring in materials and labor with pre-bent or field fabricated rebar reinforcement. Conventional brick ledge forms must be reinforced with a line of horizontal rebar and stirrups between the horizontal bars in both the ledge and the wall area of the brick ledge form. It is a single pre-assembled, 4ft (1.2m) long deformed welded wire reinforcement piece that is placed directly into Amvic’s brick ledge. The Amvic Brick Ledge Reinforcer is an engineered ICF brick ledge reinforcement system that is designed to replace conventional rebar in the Amvic ICF brick ledge forms. Rigid insulation panel for under slab depressurization systemsīrick Ledge Reinforcer for ICF construction High Density Flat Sheet Rigid Foam InsulationĮxterior Insulation Panel With a Vertical Drainage System

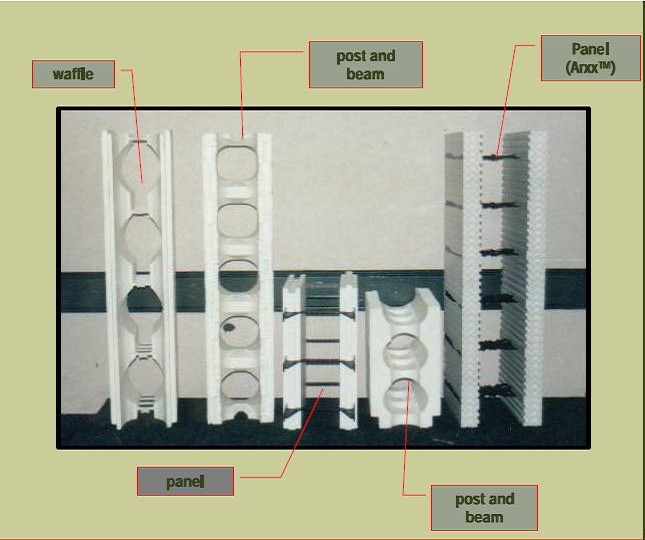

The unique feature of the Knockdown ICF System is that forms ship flat in bundles and the appropriate bridges are then used to create the needed form core size. High Density Rigid Foam Reflective Insulation BuildBlock Knockdown ICF System is a patented ICF building system that uses interlocking EPS foam blocks to create a formwork for reinforced concrete walls. Our independent panels may also be assembled and positioned differently on the opposite side of wall, panels can be up or down, left or right from each other.Ampex Insulated Hydronic Radiant PEX PanelĬarbon Graphite Embedded EPS for Exterior Wall Insulationįlat Sheet Rigid Foam Insulation With Integrated Furring Also allows for one side of wall with webs / spacers to be constructed for easy and complex rebar and stirrups placement.

Icf blocks sizes install#

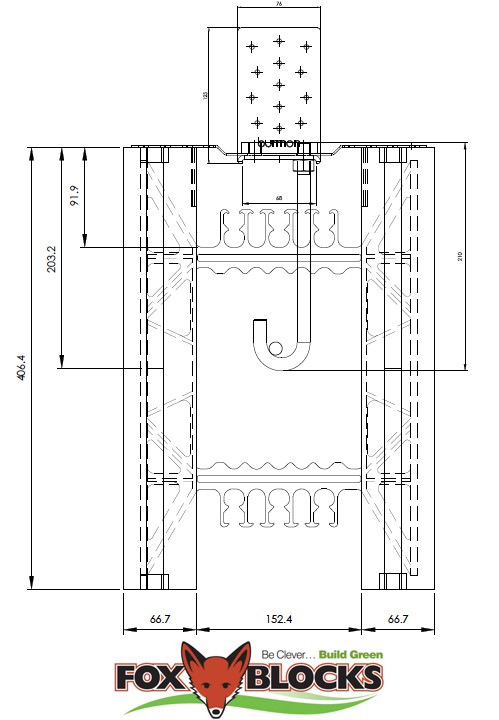

Easy slide in web / spacers (inside the panel's plastic inserts / studs) also allows to quickly install forms around rebar (seismic & multi-level design) and steel columns without having to drop forms from a ladder, scaffold or a boom. Each panel provides embedded vertical fastening / stud at every 8in (203 mm) on center. This block has six strong, full-length, injection molded plastic ties made from Polypropylene (PP) regrind resin that are well marked with the words Fox Blocks located on both sides of the block. They may also be mitered to form corners and curved walls. The 90 Degree Corner Block typically makes up 15-20 of the ICF wall assembly on most residential and commercial jobs. Standard panels are the same unit for all concrete core sizes and for building walls, columns and footings. Because they interlocks in any configurations, cut panels are also used in the wall assembly creating very little to no waste. IntegraSpec's Standard panels are THE ULTIMATE and the only UNIVERSAL, INDEPENDENT panel having with NO TOP, BOTTOM, LEFT OR RIGHT SIDE.

The IntegraSpec High Impact Polystyrene (HIPS) plastic inserts are bonded / fused within the IntegraSpec Expanded Polystyrene (EPS) foam panels making IntegraSpec the strongest ICF system on the market with having the fastest pouring rate using high slump or self leveling concrete to eliminate cold joints, voids, honeycombing, crooked and wavy walls.

Icf blocks sizes free#

Unlike other ICFs, IntegraSpec's Independent panel allows to free form any shape and any size of walls, footings, columns without being hand-cuffed like an ICF block which only installs like a masonry product concept.

IntegraSpec is the original bi-directional, reversible and perpendicular interlocking ICF building system with No Top, Bottom, Left and Right Forms.

0 kommentar(er)

0 kommentar(er)